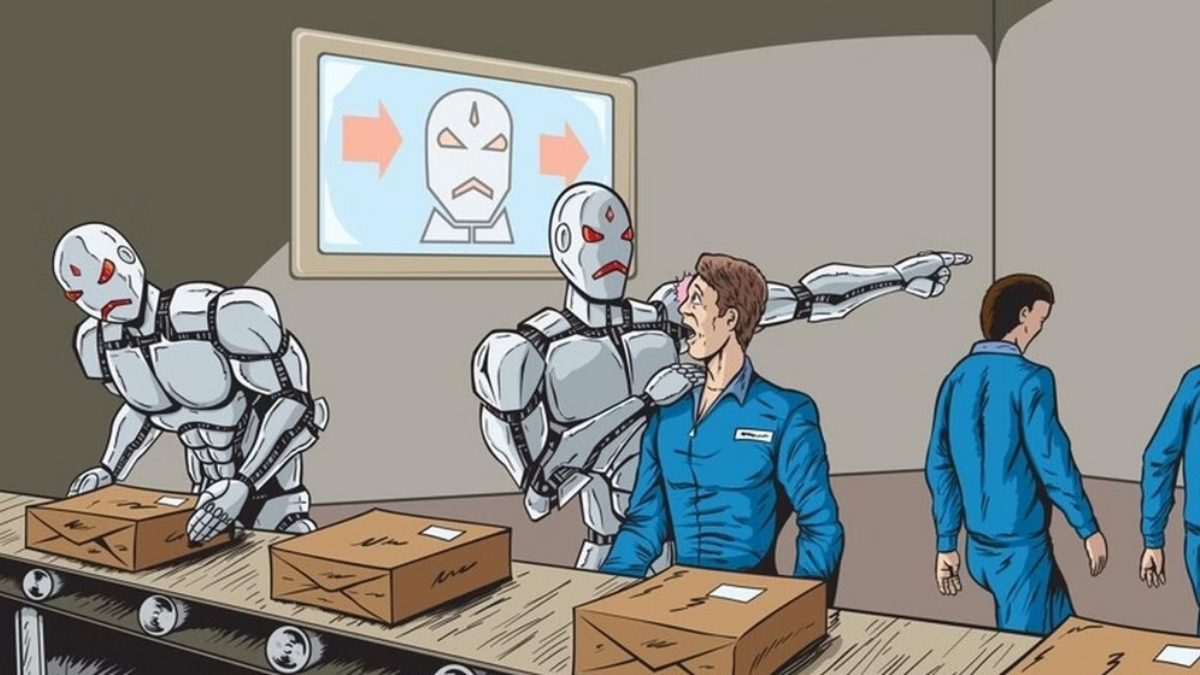

Imagine a world where robots don’t just assemble gadgets in the background—they step in as full-fledged teammates, handling the grunt work with precision humans can only dream of. That’s the future Xiaomi’s CEO, Lei Jun, painted recently, and it’s closer than you think. Within half a decade, humanoid robots could overhaul manufacturing lines, snatching up roles that rely on steady hands and tireless focus. But here’s the kicker: this isn’t about doomsday job losses; it’s a pivot toward smarter, safer ways of building the stuff we love. Let’s dive into how this shift is unfolding, straight from the folks at Xiaomi.

Xiaomi’s Bold Bet on Bots in the Factory

Xiaomi isn’t dipping a toe into robotics—they’re diving headfirst. Back in 2022, they unveiled CyberOne, their sleek humanoid prototype that turned heads with its emotional AI smarts and agile moves. Fast forward to today, and Lei Jun’s laying out a roadmap that’s equal parts exciting and eye-opening. In an interview with Beijing Daily, he revealed plans to roll out these bots across Xiaomi’s factories on a massive scale by 2030. Why? Because repetitive, precision-driven tasks—like inspecting massive car parts or tweaking assembly lines—are begging for automation.

Think about it: in their electric vehicle plants, Xiaomi’s already using AI-powered X-ray scanners hooked up to vision models. These systems eyeball huge die-cast components in just two seconds flat—ten times faster than a human inspector, with over five times the accuracy. No more coffee-fueled shifts scanning for flaws; bots handle the tedium, freeing up workers for creative problem-solving. Lei calls this the dawn of AI as a “core force,” not some shiny add-on—it’s the engine rebuilding how industries tick.

And the numbers back it up. Analysts peg the global market for industrial humanoid robots at around $140 billion by the end of the decade, fueled by demands for speed and reliability. Xiaomi’s not alone in this race—giants like Tesla with their Optimus bots are nipping at heels—but their focus on seamless factory integration gives them an edge. It’s like upgrading from a flip phone to a smartphone: once you see the potential, there’s no going back.

Which Jobs Are on the Robot Radar?

So, what exactly are these humanoid helpers eyeing? Lei didn’t mince words—it’s the hands-on factory gigs that demand consistency over creativity. We’re talking roles where boredom meets burnout, and where a slip-up could mean costly recalls. Here’s a quick rundown of the hotspots:

- Assembly Line Workers: Picture bolting together smartphone casings or EV batteries hour after hour. Humanoids excel here, with their endless stamina and sub-millimeter precision, cutting error rates by up to 90% in similar setups (per McKinsey’s automation reports).

- Quality Inspectors: From spotting welds on circuit boards to checking paint jobs on vehicles, these bots use cameras and sensors to flag issues faster than the eye can blink—remember that two-second X-ray scan? It’s a game-changer.

- Material Handlers: Lugging heavy parts across the floor? Robots like CyberOne are built for it, reducing workplace injuries that plague manufacturing (the U.S. Bureau of Labor Statistics notes over 400,000 such incidents yearly).

- Packaging and Sorting Pros: End-of-line tasks, like boxing gadgets or sorting defects, are ripe for takeover. Humanoids can adapt on the fly, learning from AI tweaks without needing a lunch break.

Of course, not every job’s doomed—ones needing empathy or on-the-spot innovation, like design engineers or team leads, stay firmly human. But for the routine stuff? Expect a shake-up. Lei warns that clinging to old-school, low-wage models won’t cut it anymore; China’s manufacturing boom hinges on this intelligent upgrade.

The Bigger Picture: Homes, Partnerships, and Why It Matters

Here’s where it gets really intriguing—Lei predicts the home market for humanoid robots will dwarf factories in size and sophistication. We’re talking bots that fold laundry, whip up dinner, or even keep an eye on the kids, all while navigating the chaos of daily life. Stricter standards mean tougher tech, but the payoff? A $100 billion-plus consumer robotics sector by 2030, according to Statista forecasts.

Yet, no one’s going solo. Lei stresses partnerships are key—think Xiaomi teaming with suppliers for sensors, software whizzes for brains, and even rivals for standards. It’s a collaborative ecosystem, much like how smartphones exploded through open alliances. For countries like China, leading this charge isn’t optional; it’s survival in a world racing toward smart production.

What does this mean for workers? Upskilling, for one—training in robot oversight or AI ethics could create millions of new roles. It’s reminiscent of the PC revolution: sure, typists faded, but coders and designers boomed. The transition won’t be seamless, but with proactive policies, it could spark unprecedented growth.

Wrapping It Up: Ready for the Robot Renaissance?

Humanoid robots aren’t villains in this story—they’re the sidekicks supercharging human potential. Xiaomi’s vision, led by Lei Jun’s sharp insights, shows us a manufacturing landscape that’s faster, safer, and downright innovative. In five years, your next Xiaomi gadget might owe its flawless finish to a bot buddy, not a weary shift worker.

Curious for more tech scoops like this? Hit that subscribe button or follow us on Facebook and WhatsApp—we’ll keep you in the loop on all things futuristic, no bots required. What’s your take—excited or a bit wary? Drop a comment below.